In a time where the sources of inventory supply (both physical and systemic) seem to be growing, retailers face an increasingly complex challenge: how to provide accurate, real time inventory data higher up in the shopping funnel to meet the demands of today’s Omni Channel fulfillment expectations. They are improving but still have a long way to go. For example, today, 59% of brands allow shoppers to filter or refine their selection to show store inventory availability (up from 50% in 2022).

Additionally, in today’s retail landscape, customers are embracing a wide variety of shopping methods, emphasizing the critical need for accurate and connected inventory systems. Customers demand not only convenience, but consistency in their shopping experiences. One study shows more than half of customers engage with three to five channels during each journey they take towards making a purchase, underscoring the importance of seamless integration to meet their evolving demands. A recent McKinsey article points out that while 75 percent of consumers want a seamless omni channel experience, only 25 percent are satisfied with the experience they are getting from retailers.

Estimated Delivery Date (EDD) has emerged as a pivotal factor in customer satisfaction, becoming a make-or-break element for retailers. When it comes to EDD promising, multiple aspects of that promise rely on an accurate and real time inventory foundation. For grocers, the ability to avoid costly substitutions is directly tied to how fast inventory is updated across the business process.

The bottom line is that as more and more fulfillment data is brought up stream in the purchasing funnel - to allow for precise EDD promising and fulfillment choices, the need for real time inventory data continues to become more important.

A scaled, accurate inventory picture is the foundation to OMNI fulfillment excellence.

- EDD promising can’t happen without it

- The right sourcing decisions

- Missed online sales

- Substitution avoidance

- Bad CX with cancels or backorders

- Share inventory position with marketplaces

- Make better decisions on sourcing related to inventory age.

- Timely markdowns based excess stock visibility.

- Faster inputs to planning systems.

Yet we find many retailers struggling with how to scale, replicate and ultimately provide accurate availability to promise pictures across the sales channels and to other internal teams and systems.

How did we get here?

Legacy inventory masters such as ERP’s or WMS systems were not designed to scale to support the rapid inquiries and commits required of today’s OMNI channel fulfillment expectations. For example, a retailer with 100K+ SKUs attempting to show estimated delivery dates on product search pages would require millions of inventory availability calls over a day. Retailers have been building scaffolding around these systems through replicated inventory pictures in the OMS and or e-commerce engine. Safety stock calculations and virtual segmentation are additional tools that have been used to protect against inaccuracy or velocity.

But this scaffolding has brought its own set of challenges.

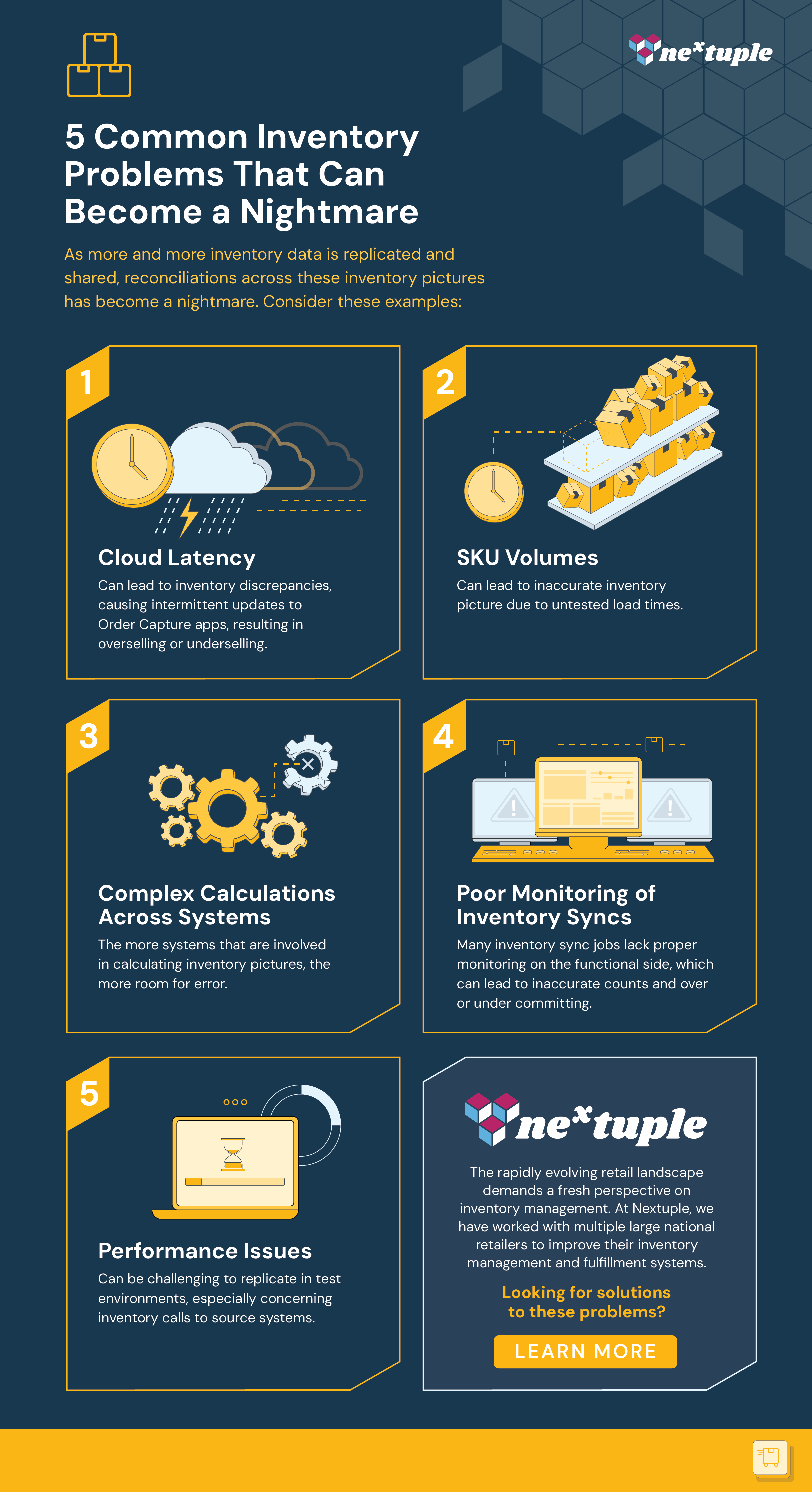

As more and more inventory data is replicated and shared, reconciliations across these inventory pictures have become a nightmare. Consider these examples:

- Cloud latency: Inventory discrepancies can arise as a result of network latencies at the cloud provider’s infrastructure. This can cause inventory updates being sent only intermittently to their Order Capture application which leads to overselling in some instances and underselling in some others.

- SKU volumes: Inventory load times are rarely tested. As a result it is common to see inaccurate inventory pictures due to long load time issues. For one paint retailer, the SKU palette combinations mix meant that the Order Capture application needed to be in sync across the 5,000 stores and 20,000 products. Inventory reconciliation issues were rampant as the three systems needed to be in sync. Inventory Source, OMS and the Order Capture application. A full sync took 3 days - far too long - resulting in order cancels and dissatisfied customers.

- Complex calculations across systems: The more systems that are involved in calculating inventory pictures, the more room for error. For one specialty/import retail store chain, their warehouse application provided an inventory picture which deducted“demand” from the “On-hand” inventory. When OMS made an inventory call to the inventory visibility application, the “demand” was again deducted leading to a case of “double dipping” and resulting in a skewed inventory picture.

- Poor monitoring of inventory syncs: Many of the inventory sync jobs lack proper monitoring on the functional side. For example, an Enterprise Resource Planning (ERP) system was responsible for capturing periodic inventory snapshots and publishing these feeds to the Inventory service. This feed included inventory statuses of positive counts, zero, and also negative numerical values. While the Inventory service handled the processing of positive and zero inventory entries, it did not provide any alerts or acknowledgement for negative inventory instances. This resulted in an overcommitment situation, as the Inventory service continued to maintain positive inventory values for these specific items, despite the presence of negative figures.

- Performance issues: Another difficult thing to replicate in test environments is the performance around inventory calls to the source systems. A typical scenario is the e-commerce application relying on a periodically updated inventory cache sourced from the inventory service. The website initiates frequent inventory service calls during various stages of the order creation process. These calls occurred during adding items to the cart, progressing through the checkout process, and finalizing the order placement. Challenges arose when the cart size expanded significantly or when there were numerous customers placing orders at the same time. The API calls started timeout, leading to disruptions in the order placement and bad inventory pictures on the front end.

What is the answer?

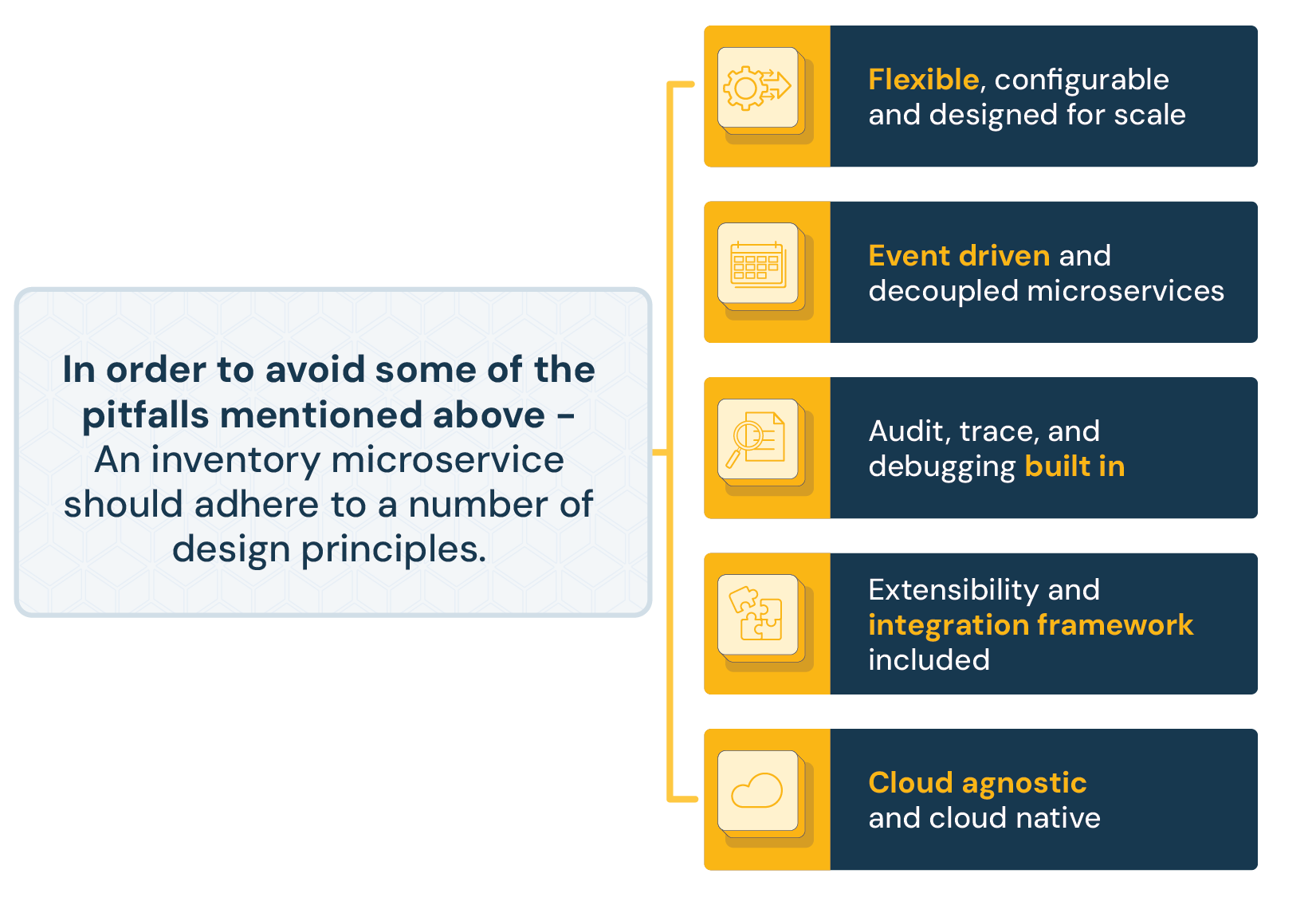

As a result of these common issues, many retailers are starting to think about an inventory service that can support the modern demands of inventory visibility and management as well as limit the associated challenges with inventory accuracy across the different views.

When evaluating the landscape, retailers should consider two main factors:

1. Operational maturity with inventory management

If your current cycle count accuracy and DC / Store fill rates are not at or above industry benchmarks, look at all the root causes both technical and operational. For any that are operational related, make sure to create a plan to address those before you invest in a new inventory management system. Do you have the proper SOP’s around inventory controls and cycle counting? Is your store fill rate performance a reflection of execution issues or system issues? This operational maturity also includes technical considerations. If you are replicating inventory pictures do you have the proper monitoring and auditing tools? Are your issues caused by poor SKU roll ups from UPC to SKU ID or downstream supplier data quality?

If you’ve achieved this operational maturity with your core inventory data it’s time to look at technical solutions.

2. Technical and functional feature sets

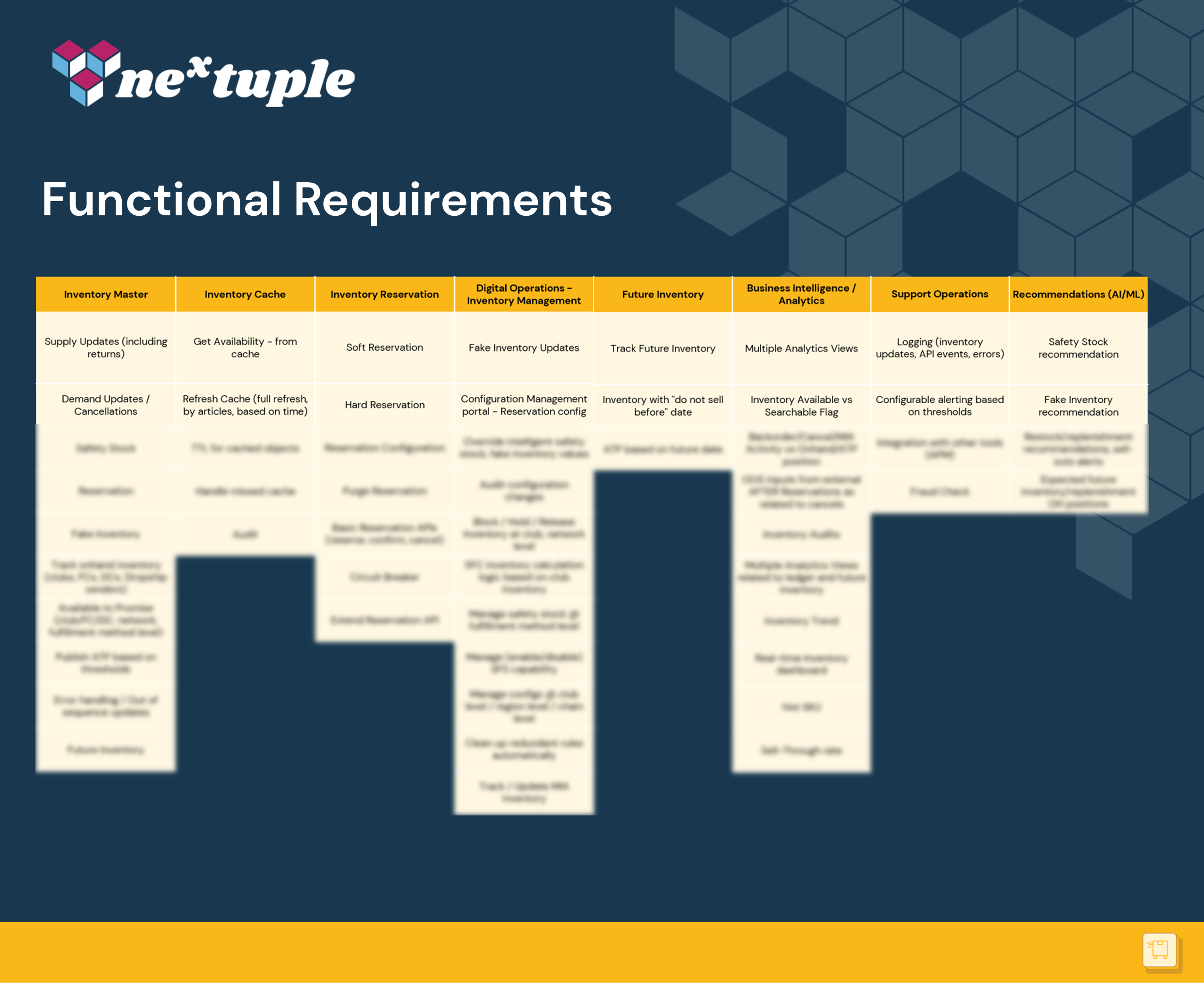

A modern inventory service should support not only your needs for scalable, accurate inventory pictures across your sales channels but also a robust set of analytics, troubleshooting and recommendation features.

We’ve helped large retail chains solve the most complex inventory visibility and management problems. Below is a sampling of the requirements you should be thinking about when selecting a new inventory management solution. Click the below image to read the full chart.

If poor inventory visibility or accuracy is blocking you from achieving your full potential, download our inventory features here to get started. If you would like to talk to someone about the value and timing of an implementation, we can quickly help you assess the business case and roadmap for an inventory master microservice.

The rapidly evolving retail landscape demands a fresh perspective on inventory management. Retailers must adapt to meet the challenges posed by Omni Channel fulfillment while leveraging technology solutions that empower them to thrive in the modern commerce era. By selecting technical solutions that align with their needs, retailers can pave the way for success in the ever evolving world of retail.

At Nextuple, we have worked with multiple large national retailers to improve their inventory management and fulfillment systems. To learn more, visit our Resources Page.

.png?width=250&height=56&name=nextuple_logo_vector%20(4).png)