In 2023, the number of retailers pursuing scaled SFS (Ship from Store) fulfillment is increasing. Recently Ulta Beauty announced that they were tripling the amount of stores doing SFS. Target is opening yet more sortation centers and here at Nextuple we’re in the middle of a modernization effort for store fulfillment that will help our client scale with E-commerce growth for the next 5 years.

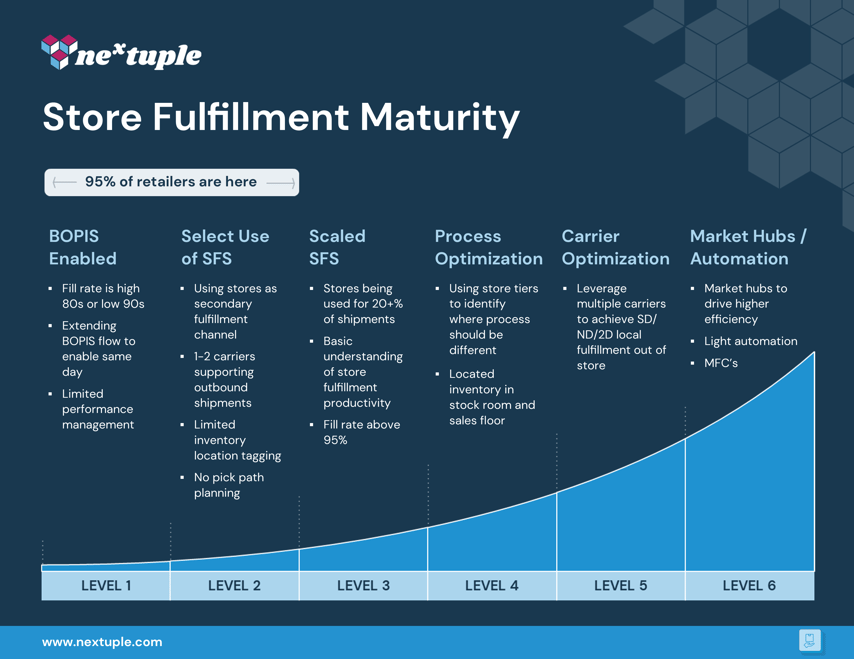

SFS is a smart strategy for retailers. Leveraging physical stores as mini distribution centers allows for faster delivery, reduces shipping costs and enhances inventory management. Yet most retailers are still not buying it. As depicted in the chart below, most retailers are at level two of the progression of scaling store fulfillment.

Reasons against store fulfillment are plentiful but in our discussions with clients, there seems to be a philosophical stance for or against it. Those “for” have a strong belief in speed and getting the inventory deployed to a location where it can be most effectively used vs. investing in fulfillment centers to hold e-commerce inventory.

Those “against” feel speed is not a differentiating factor and the efficiency of SFS will never match that of a modern warehouse. They feel they lack the space, labor, or focus to achieve scaled SFS.

At a higher level, it comes down to a retailer's belief in maximizing stores to achieve their OMNI channel outcomes. Over the last two years, Walmart has been focusing its efforts on store fulfilled delivery, with sales nearly tripling in that time. The company is now seeing more than $1 billion a month in that category.

In this post we’d like to offer some ideas to help those of you already starting the journey of scaled SFS and perhaps motivate the rest of you to think about the possibilities further.

There are 3 key areas we’d like to discuss that have the most relevance in scaling your store fulfillment operations.

1. How productive are you when picking items?

2. Should you be thinking about process variation across your store?

3. What kind of performance management are you doing?

It’s clear the role of the store in OMNI channel fulfillment is not going to recede in years to come. While some industry leaders are making significant strides in embracing SFS, many retailers remain cautious about its potential benefits. The divide seems to revolve around differing philosophies, some emphasizing the speed and agility of SFS to deploy inventory efficiently, while others argue for the efficiency of modern warehouses.

In a rapidly evolving landscape, companies who choose to embrace scaled SFS while addressing the challenges and considerations we mentioned above can position themselves for success in the era of e-commerce growth.

Whether you’ve chosen to double down on those assets or not, hopefully we’ve inspired you to think about how you can make your stores more productive while improving the employee experience at the same time.

Is your current set of store fulfillment tools able to provide you with the flexibility and process variation we’ve outlined here? At Nextuple not only have we deployed the tech but we have hands-on experience operating store fulfillment at scale, helping some of the largest retailers go after these improvements. We’d love to help you on your journey! To learn more, read our eBook Modernizing Omnichannel Fulfillment Technology Landscape.

FAQs

Is there a specific point where SFS becomes more cost-effective than traditional fulfillment methods?

The answer depends on several factors specific to your business. The profile of your online orders plays a role. If your online sales are dominated by smaller items with a wide geographic spread, SFS could be a good fit. The potential for faster deliveries and reduced per-order shipping costs makes it an attractive option. Additionally, a dense network of stores located close to your customer base strengthens the case for SFS. These stores can function as mini-fulfillment centers, fulfilling orders quickly without requiring substantial additional investment.

Another factor to consider is warehouse efficiency. If your existing warehouses are already stretched thin, expanding might incur significant costs for additional space, staffing, and equipment. SFS could be a way to alleviate some of the fulfillment burden without a large upfront investment.

The key to making an informed decision lies in a comprehensive cost analysis that goes beyond just shipping costs. This analysis should consider factors like the expenses associated with warehouse expansion, such as construction or leasing costs for additional space, staffing needs, equipment requirements, and any necessary technology upgrades. On the SFS implementation side, the analysis should account for technology upgrades to support in-store fulfillment processes, potential modifications to store layouts, and any additional staff required to handle SFS operations. Finally, the increased complexity of managing inventory across multiple locations should also be factored into the cost comparison.

How can retailers ensure they have the right stock in the right locations to fulfill SFS orders efficiently?

For SFS to function efficiently, retailers need a robust system to ensure they have the right products in the right locations to fulfill online orders promptly. This requires a multi-pronged approach.

Firstly, retailers need to invest in sophisticated inventory management software that provides real-time data on stock levels across all locations. This allows for better forecasting and allocation of inventory, ensuring stores aren't depleted of popular items while the central warehouse holds excess stock.

Secondly, implementing clear inventory allocation rules is crucial. These rules should determine which stores hold specific products and in what quantities. Factors like local demand patterns and store proximity to customers should be considered when allocating inventory.

Finally, fostering a culture of data-driven decision making within the organization is essential. Store staff and central planners need to be trained to interpret inventory data and make informed decisions about stock replenishment and transfers. By combining these strategies, retailers can navigate the complexities of SFS inventory management and ensure efficient order fulfillment.

Will increased picking activity for online orders disrupt in-store shopping or strain staff availability to assist customers?

The increased activity of picking online orders could potentially disrupt the flow of in-store shopping or stretch staff thin, making it harder for them to assist customers on the floor.

To mitigate these drawbacks, retailers need to carefully consider store layout and staffing. Optimizing store layouts to create dedicated picking zones can help minimize disruption to browsing customers. Additionally, analyzing peak picking times and strategically scheduling staff can ensure there are still enough associates available to assist in-person shoppers during busy periods. Clear communication between staff and customers can also help manage expectations. By implementing these strategies, retailers can leverage SFS while still prioritizing a positive in-store experience.

.png?width=250&height=56&name=nextuple_logo_vector%20(4).png)